SOLUTIONS

Add value to your entire manufacturing process using smart Güdel automation solutions

Please choose your industry:

Please choose your area:

| description | industry | process | modal | |||

|---|---|---|---|---|---|---|

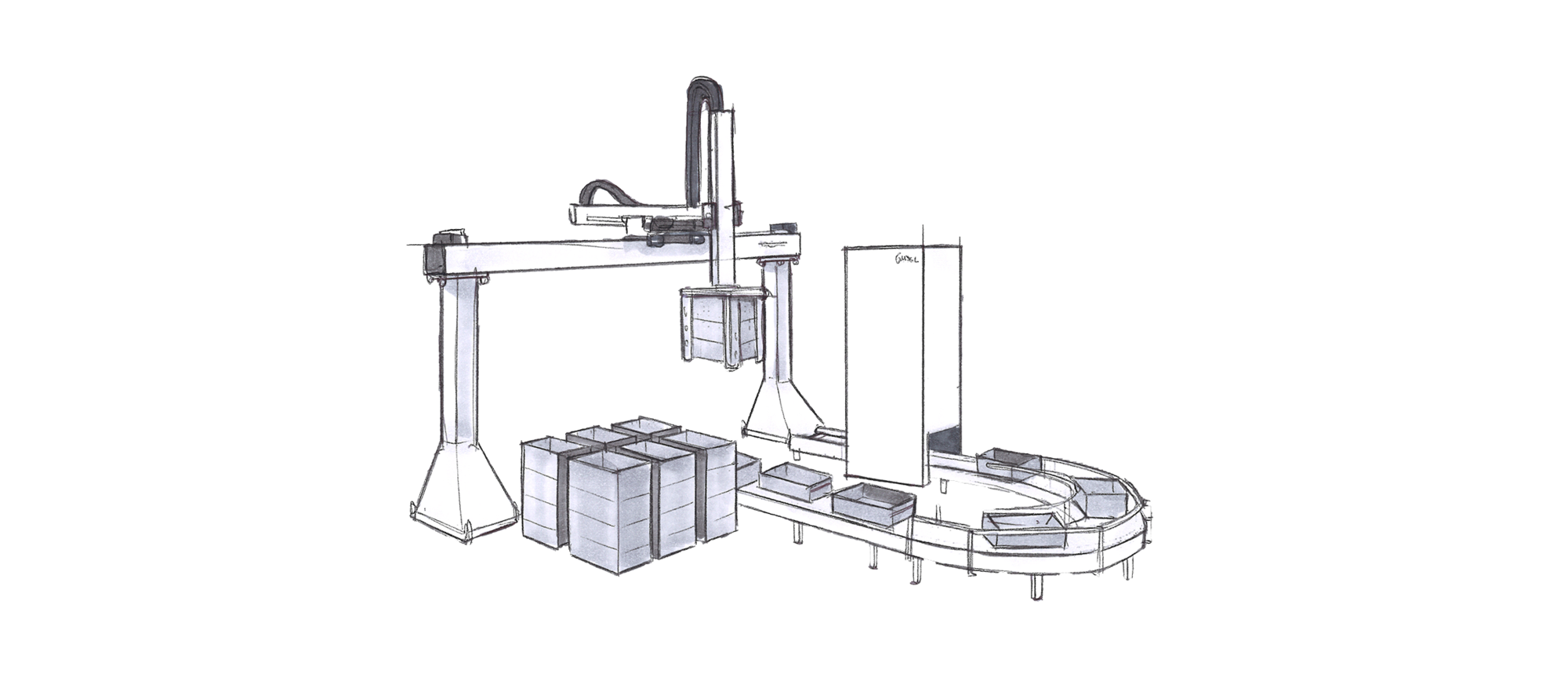

Automated crate picking in accordance with online ordersJust-in-time and just-in-sequence order picking directly into distribution channels |

Automated crate picking in accordance with online ordersJust-in-time and just-in-sequence order picking directly into distribution channels |

Details |

Designed specially for order picking in online commerce, we offer automation solutions for sorting, storing and provisioning directly from your individual order processing function – meaning that together we can make your intralogistics and mode of operation even more efficient! We offer both turnkey systems including material flow, conveyor technology, and warehouse management, and individual modules tailored to your existing system.

Interested? |

,8093, | ,7777, | modal-solution-8770 |

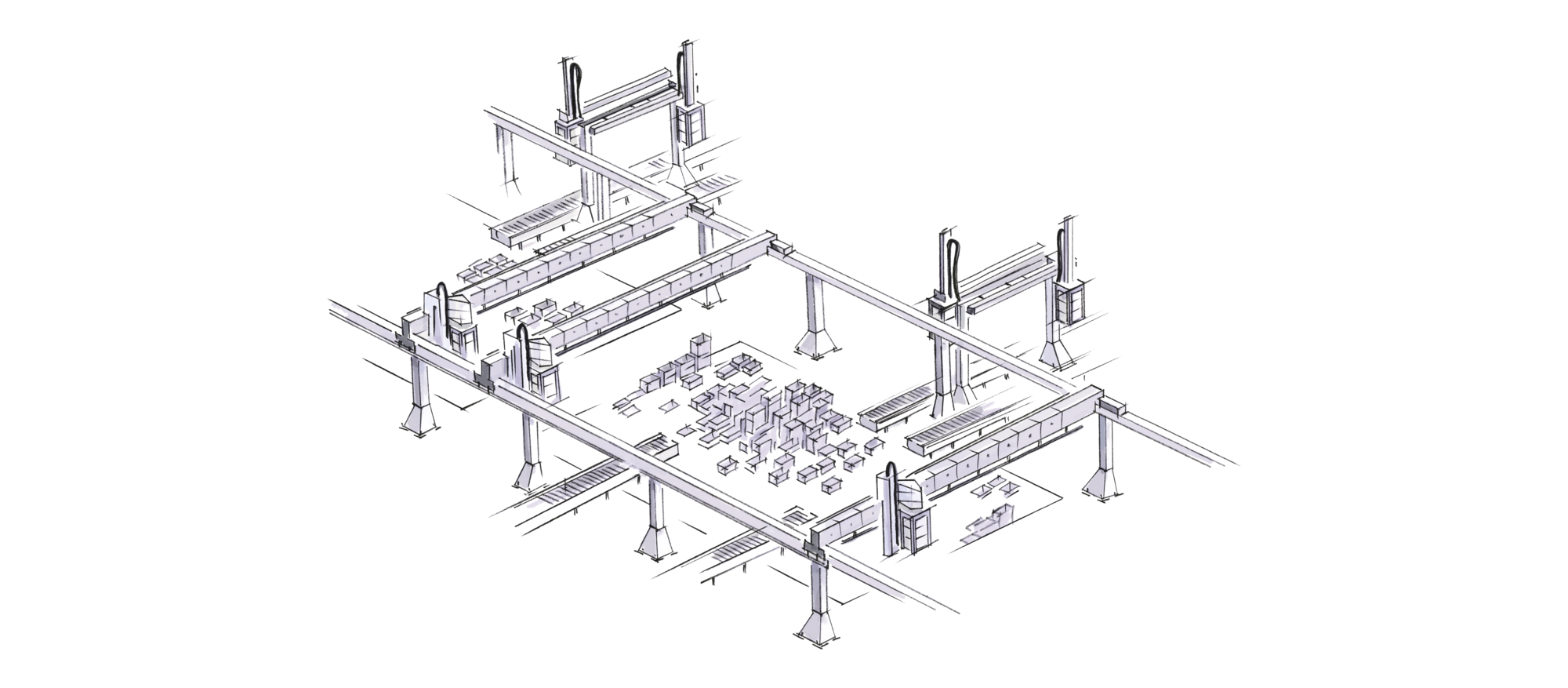

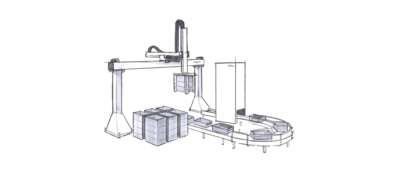

Automation solutions in logisticsEfficient material flow for your intralogistics |

Automation solutions in logisticsEfficient material flow for your intralogistics |

Details |

Ease of operation, high power throughput, excellent availability, and high storage density: our systems for fully automatic rack servicing will raise your intralogistics to a new level of efficiency and give the term "material flow" a whole new meaning.

Interested?

|

,8093, | ,7777, | modal-solution-8003 |

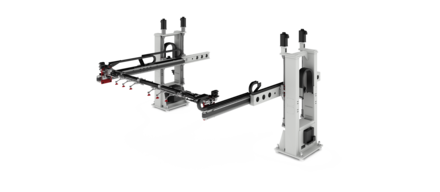

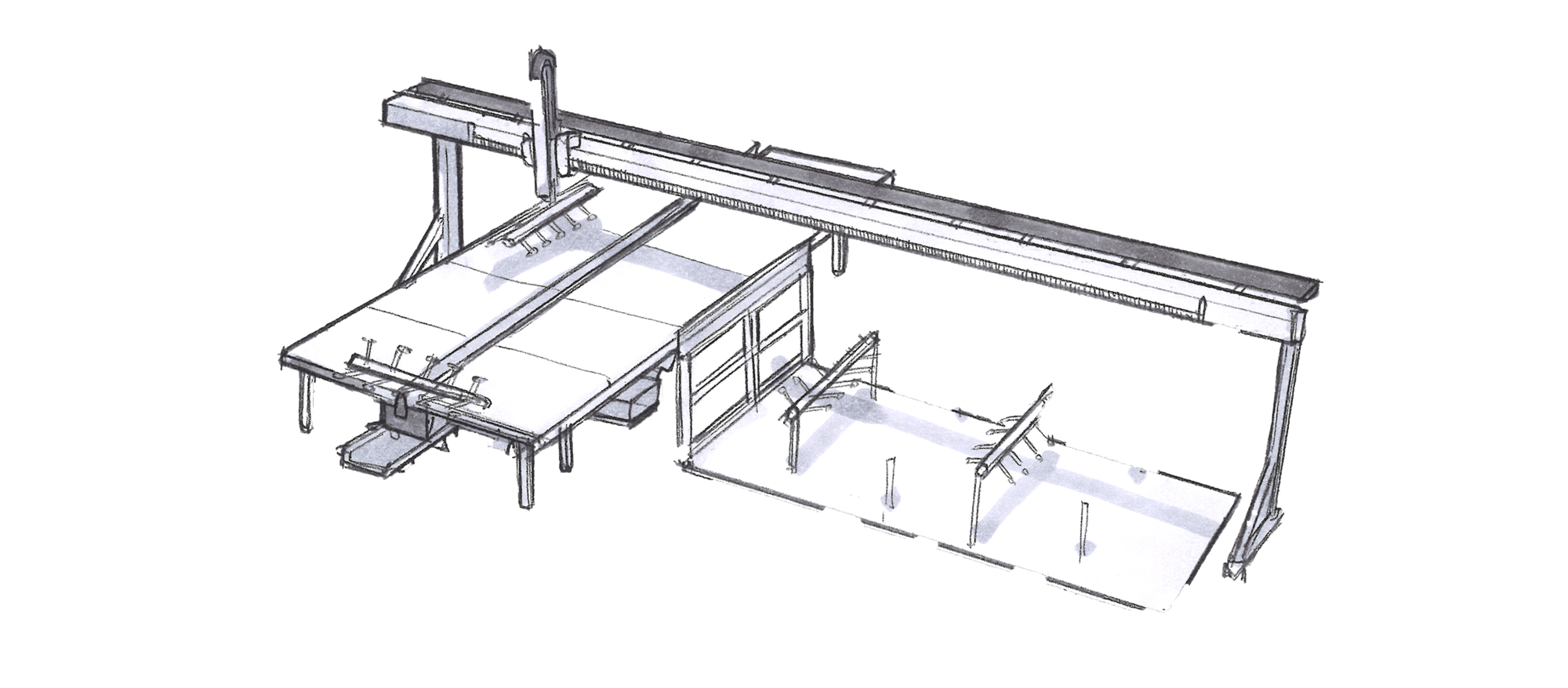

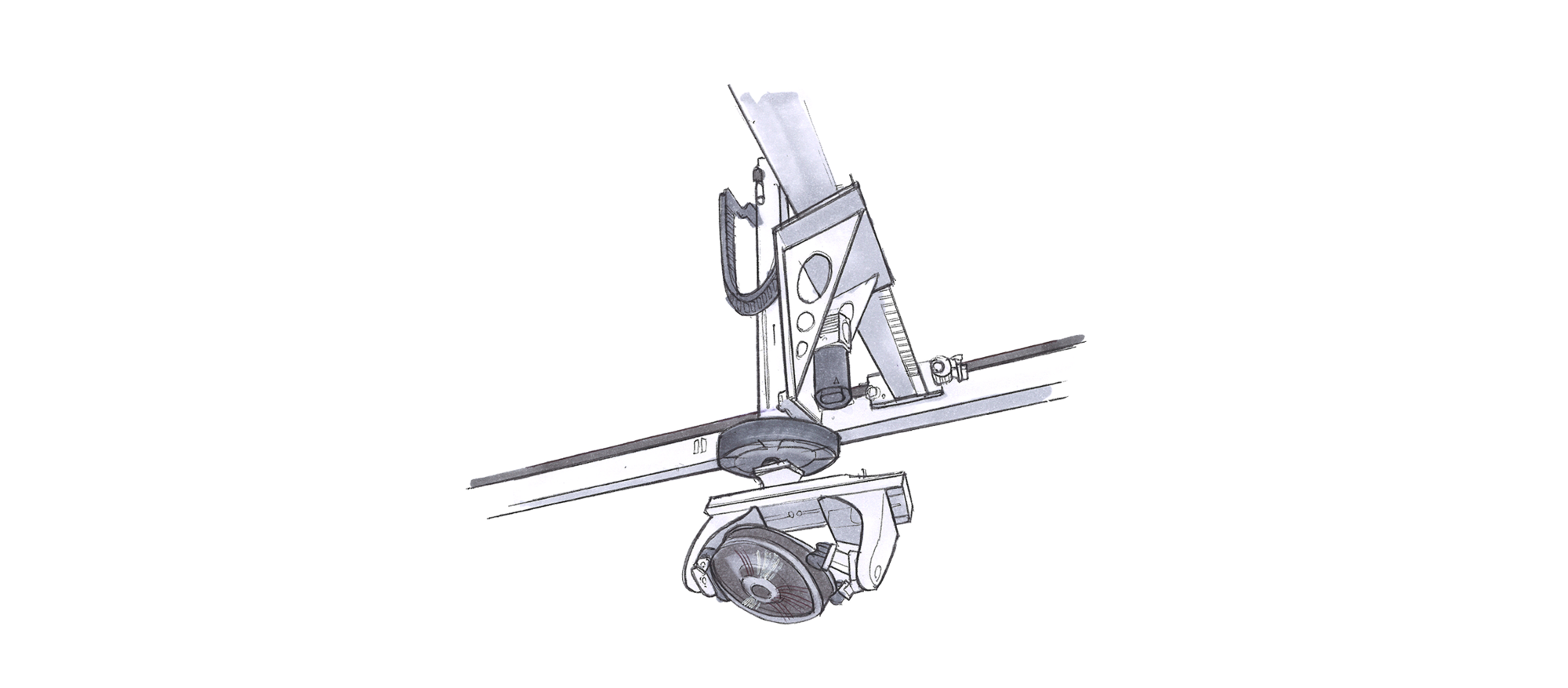

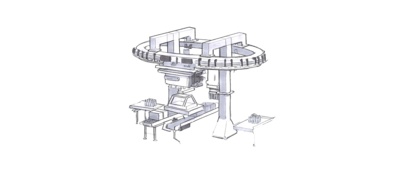

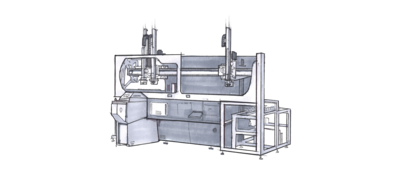

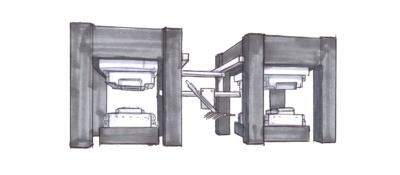

Blank Destacking System – Automatic fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Blank Destacking System – Automatic fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Details |

The Güdel blank destacking system is dedicated for feeding blanks to high speed tandem press lines. The fully automatic fanner magnets are positioned on a separate frame to ensure that the blank carriages can be easily loaded. The use of two scissor-lift tables for each blank carriage allows single and double blanks to be simultaneously processed even with different blank thicknesses. Aluminum blanks can be separated using blowing nozzles and processed in conjunction with vacuum conveyors without productivity loss. The combination of an optical parts recognition system and a centering station equipped with servo axes ensures that the entire spectrum of parts can be processed without the need for manual limit stops. Interested?

|

,8088, | ,7766, | modal-solution-7732 |

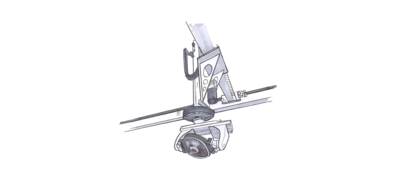

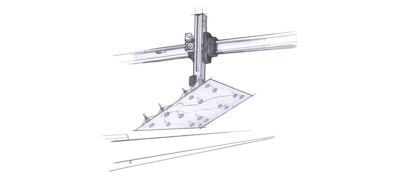

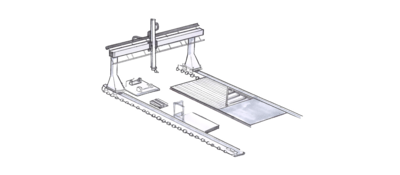

Blank Destacking System – Manual fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Blank Destacking System – Manual fanner magnet adjustmentFeeding blanks to high speed tandem press lines |

Details |

The Güdel blank destacking system is dedicated for feeding blanks to high speed tandem press lines. The fanner magnets are moved towards the blank stack manually by means of the easy-to-use rotary arms. Blowing nozzles located next to the fanner magnets enable aluminum blanks to be processed. The system is also suitable for processing single and double blanks.

The combination of an optical parts recognition system and a centering station equipped with servo axes ensures that the entire spectrum of parts can be processed without the need for manual limit stops.

Interested?

|

,8088, | ,7766, | modal-solution-7537 |

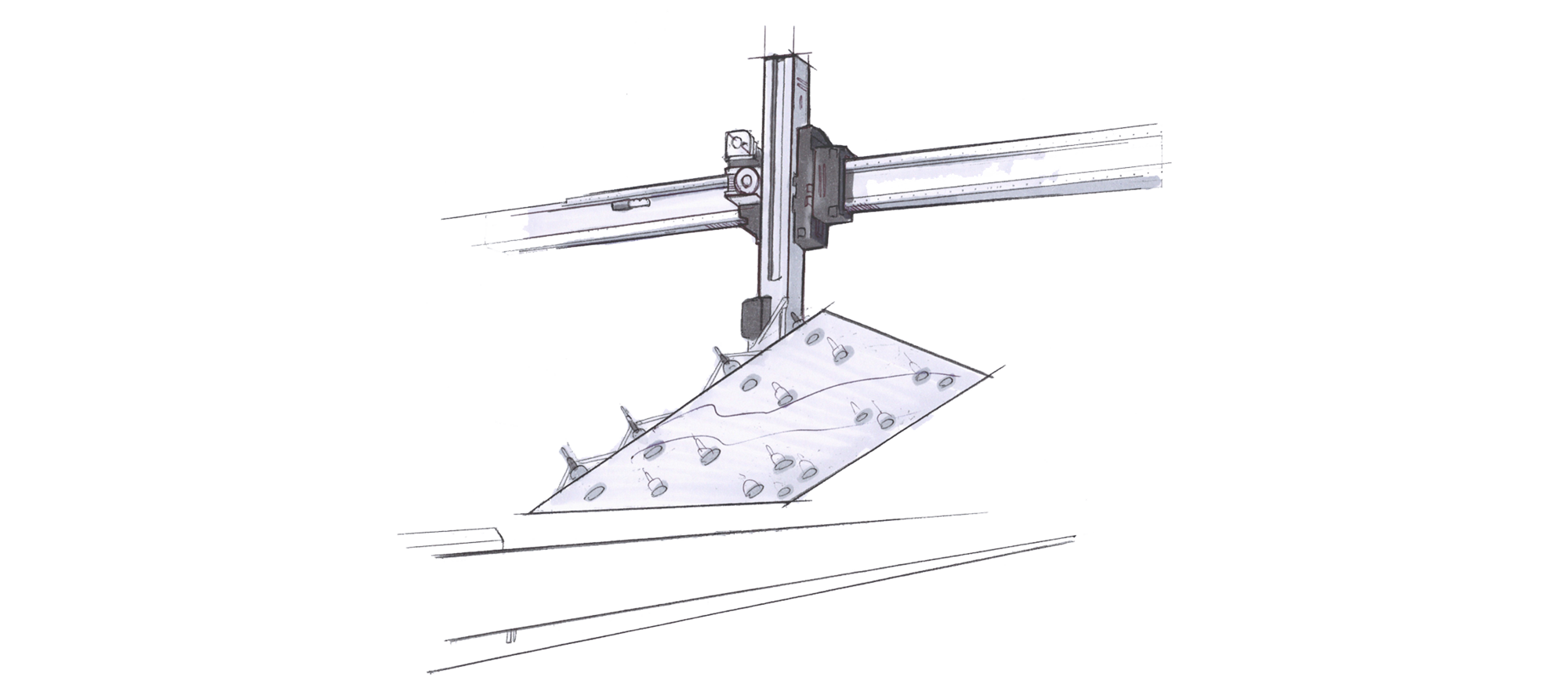

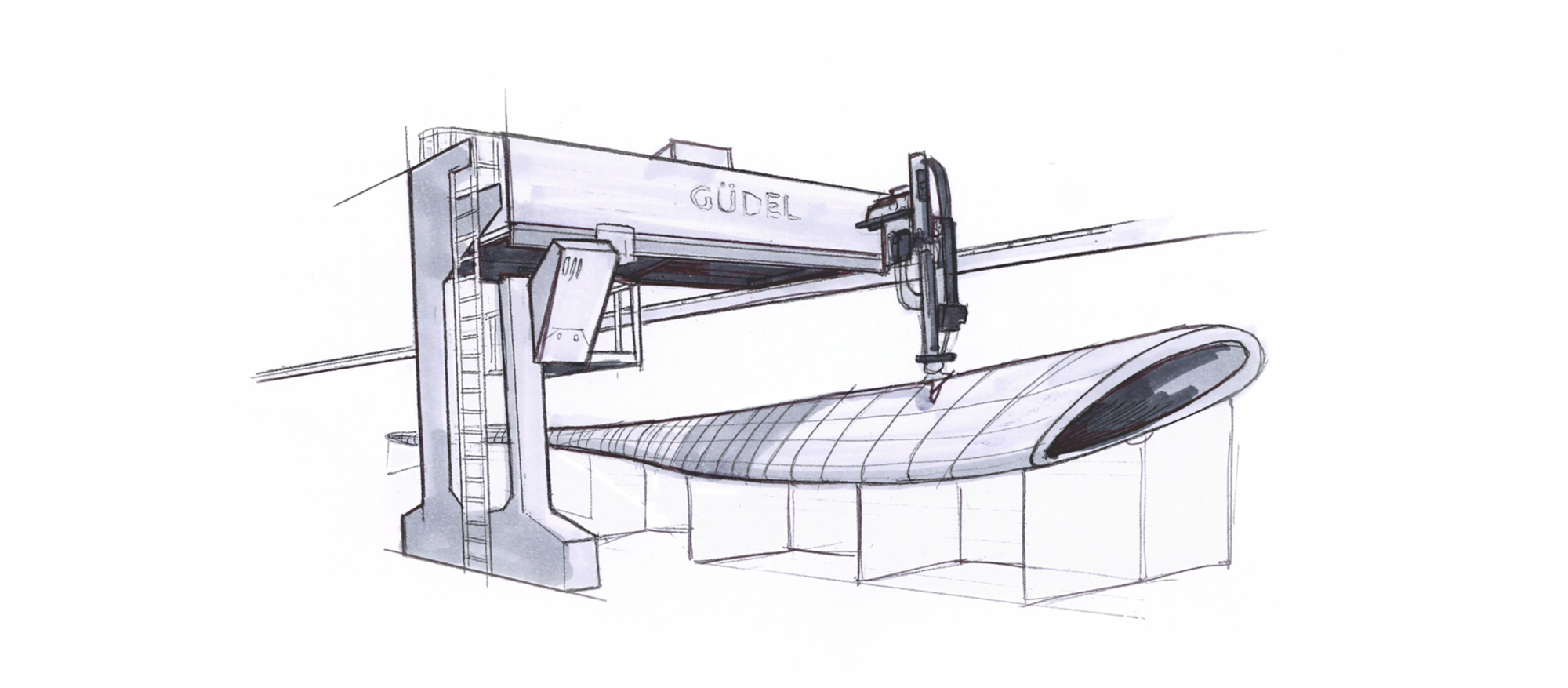

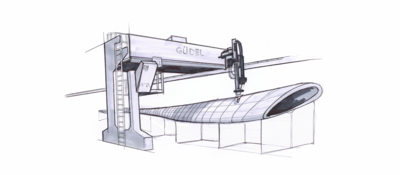

Composite manufacturingAutomation solutions for the complete CFRP production process |

Composite manufacturingAutomation solutions for the complete CFRP production process |

Details |

We offer automation solutions for your complete carbon-reinforced plastic manufacturing process. Sub-processes, such as individual work steps in the preparation or processing of surfaces, cleaning molds, layering materials or universal holding fixtures can be automated with our solutions.

Interested? |

,8090, | ,7773, | modal-solution-7996 |

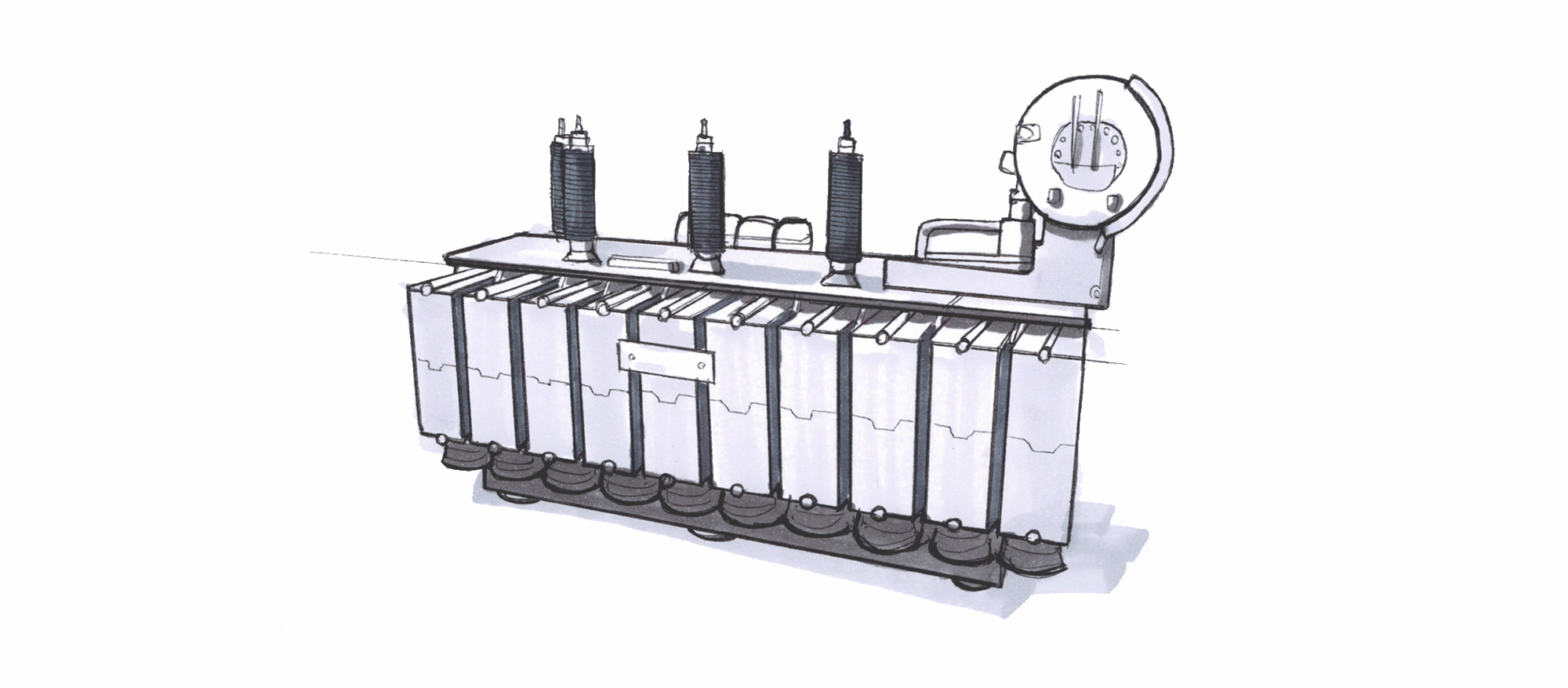

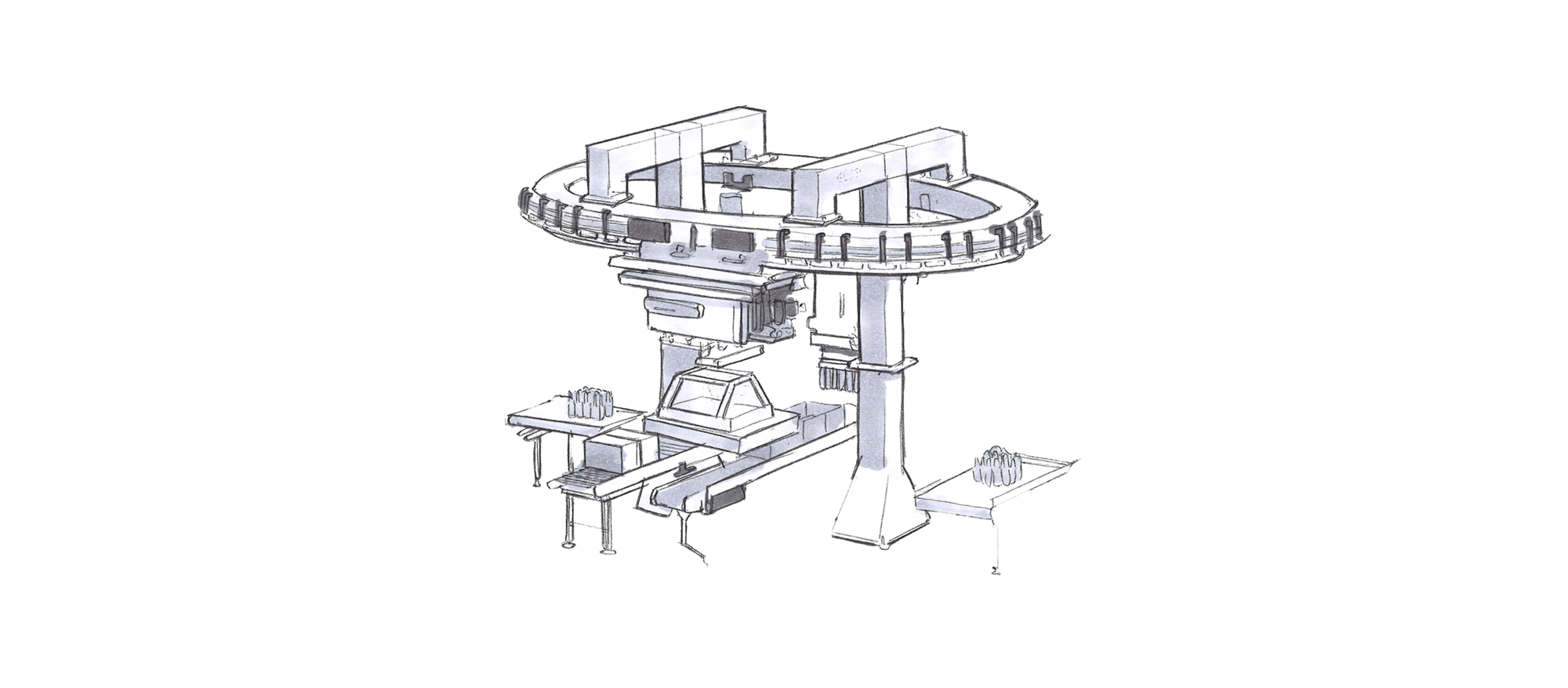

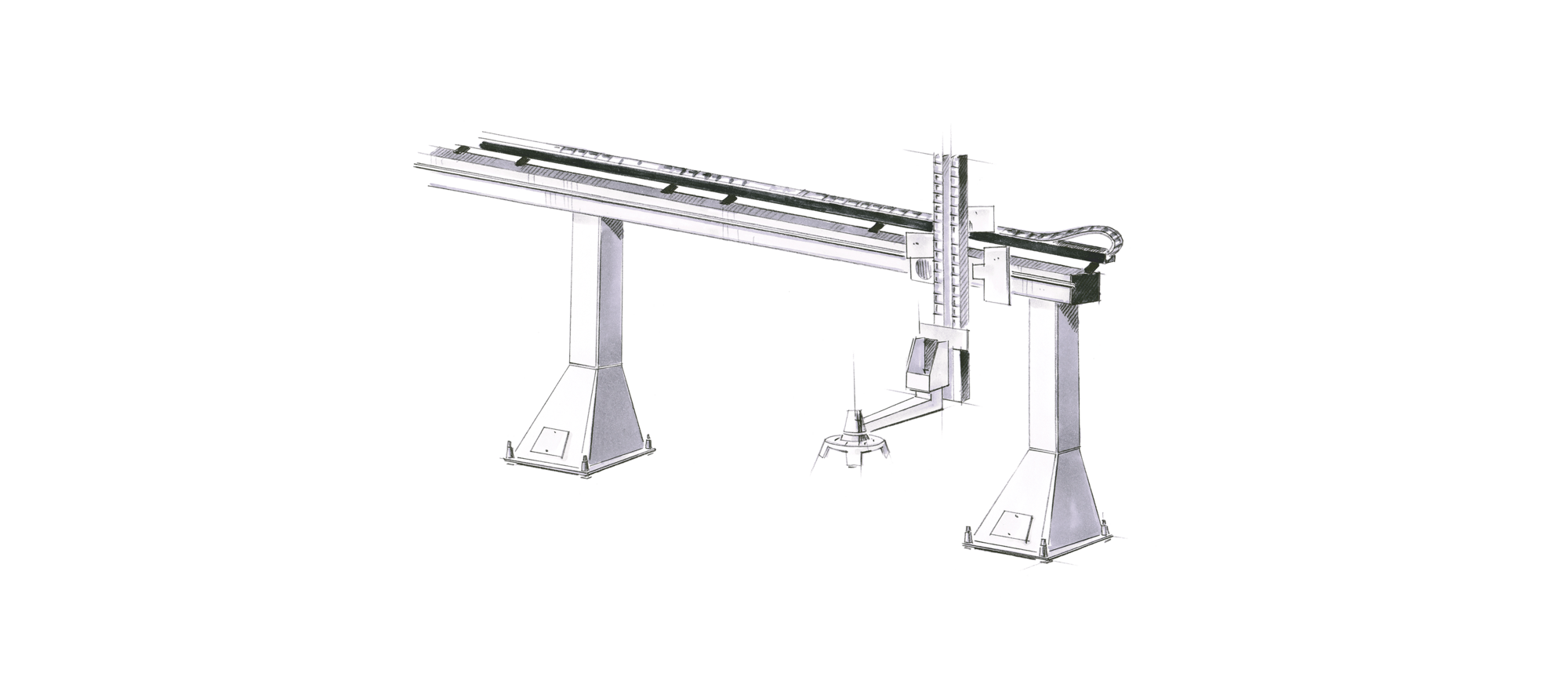

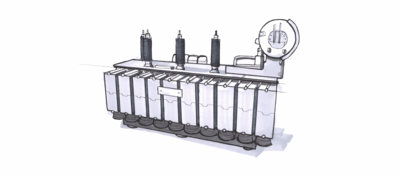

Core stackingAutomatic transformer core stacking |

Core stackingAutomatic transformer core stacking |

Details |

For better results in much less time: based on our gantry robots, we have developed an automatic core stacking system designed for use with power and distribution transformers ranging from 50 kg to 350 tons. Thanks to their accurate positioning and precision, the gantry robots can manage without external centering units – therefore significantly reducing production times.

Interested?

|

,8095, | ,7778, | modal-solution-7994 |

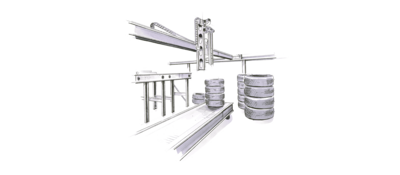

Crate logistics solutionsTransporting and storing |

Crate logistics solutionsTransporting and storing |

Details |

We offer optimum automation solutions for crate transportation and storage in the vegetable, meat and cheese processing sectors of the food industry. Outstanding advantages include ease of operation, high power throughput, excellent reliability and high storage density.

Interested? |

,8091, | ,7774, | modal-solution-8000 |

End of Line – Semi-automaticSwift, ergonomic stacking of finished parts |

End of Line – Semi-automaticSwift, ergonomic stacking of finished parts |

Details |

A particularly striking feature of our semi-automatic finished parts stacking solution is its excellent cost-benefit ratio. The EOL solution allows finished parts to be arranged ergonomically on the removal belt, so that the parts can be manually removed more swiftly and carefully. Equipped with a gantry and a parts shuttle with integrated separating units, the system is flexible enough to place the parts almost anywhere on the outlet conveyor. Interested?

|

,8088, | ,7766, | modal-solution-7911 |

Handling of railway wheelsSkilled handling of heavyweights |

Handling of railway wheelsSkilled handling of heavyweights |

Details |

The considerable weight of railway wheels plays a significant role in their handling. With the use of special grippers, parts weighing up to 1,200 kg can be gripped and turned through 180° in spite of any deformations. We can also work with you to find suitable solutions for other challenges in this or similar areas.

Interested?

|

,8094, | ,7787, | modal-solution-7992 |

Handling panes of glassGlass handling with great precision and reliability |

Handling panes of glassGlass handling with great precision and reliability |

Details |

No question: great reliability and precision are called for when loading, unloading, and handling glass sheets. If the panes weigh several hundred kilos or measure several square meters,the systems dealing with them must be designed to cope. We have a system suited to many of the challenges involved in handling panes of glass. And if a solution for your individual requirements does not yet exist, we can simply work with you to develop it.

Interested? |

,8089, | ,7771, | modal-solution-7989 |

Handling, commissioning, and palletizing everything from green to finished tiresEfficient handling of green to finished tires |

Handling, commissioning, and palletizing everything from green to finished tiresEfficient handling of green to finished tires |

Details |

Güdel provides automation solutions for handling, commissioning, and palletizing everything from green to finished tires. The Green Tire Tray is yet another example of Güdel's innovative spirit. Using this special pallet, green tires can be transported more quickly and without damage. Güdel is your premium partner for all your needs when it comes to handling green and finished tires.

Interested?

|

,8300, | ,, | modal-solution-8001 |

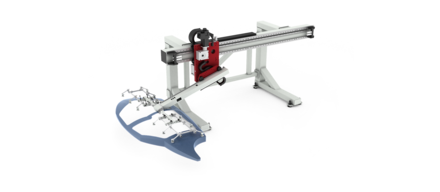

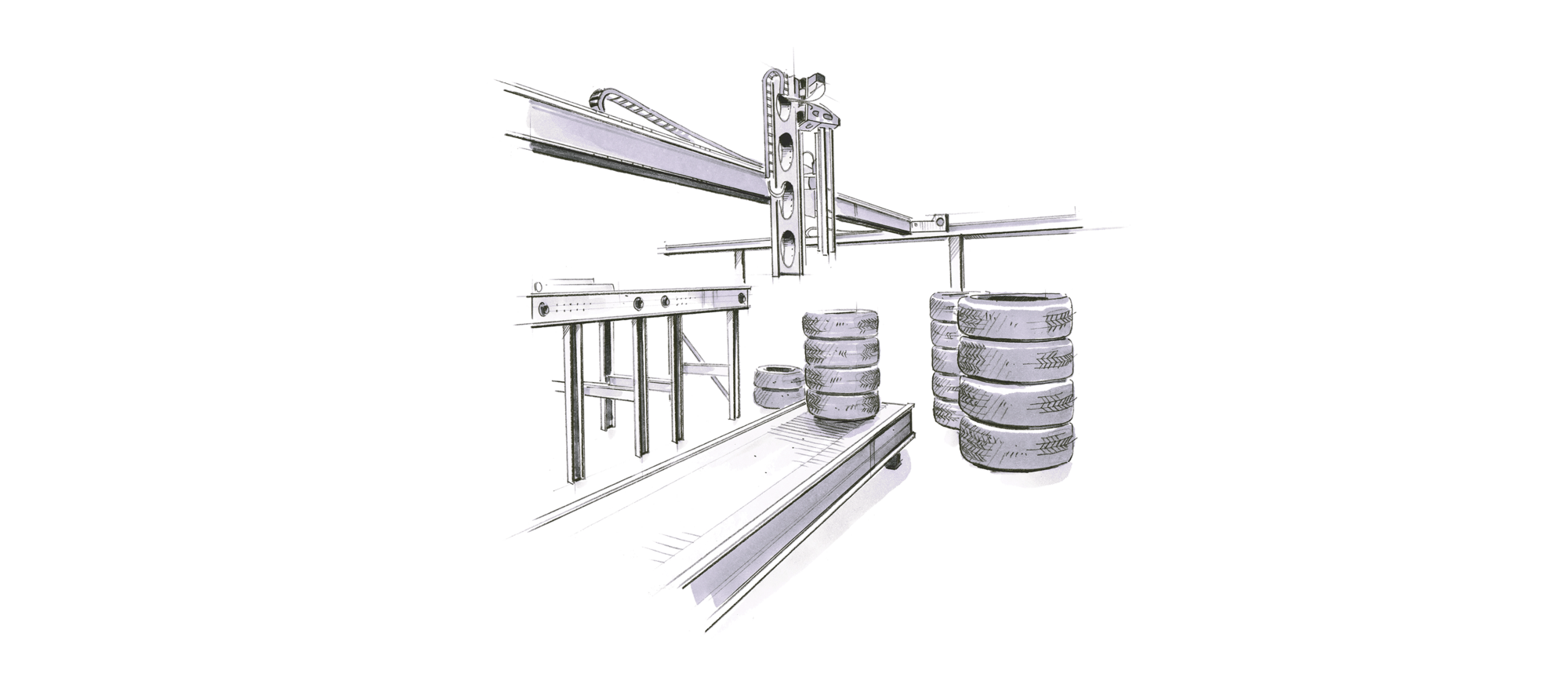

Handling, storing and press delivery of green tiresThe right flow for automated green tire handling |

Handling, storing and press delivery of green tiresThe right flow for automated green tire handling |

Details |

Combined with our extensive tire gripper experience, our linear axes form the perfect basis for the automation of your processes - from storing the green tires after construction to their delivery to the curing presses. Make your automated green tire handling flow even better – and exploit the flexibility offered by our modular designs in the process. We can offer you individual components or turnkey systems, tailored to your personal needs.

Interested?

|

,8300, | ,8458, | modal-solution-8455 |

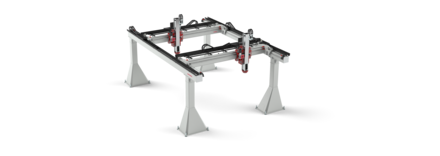

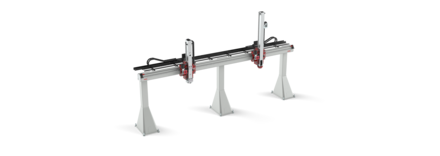

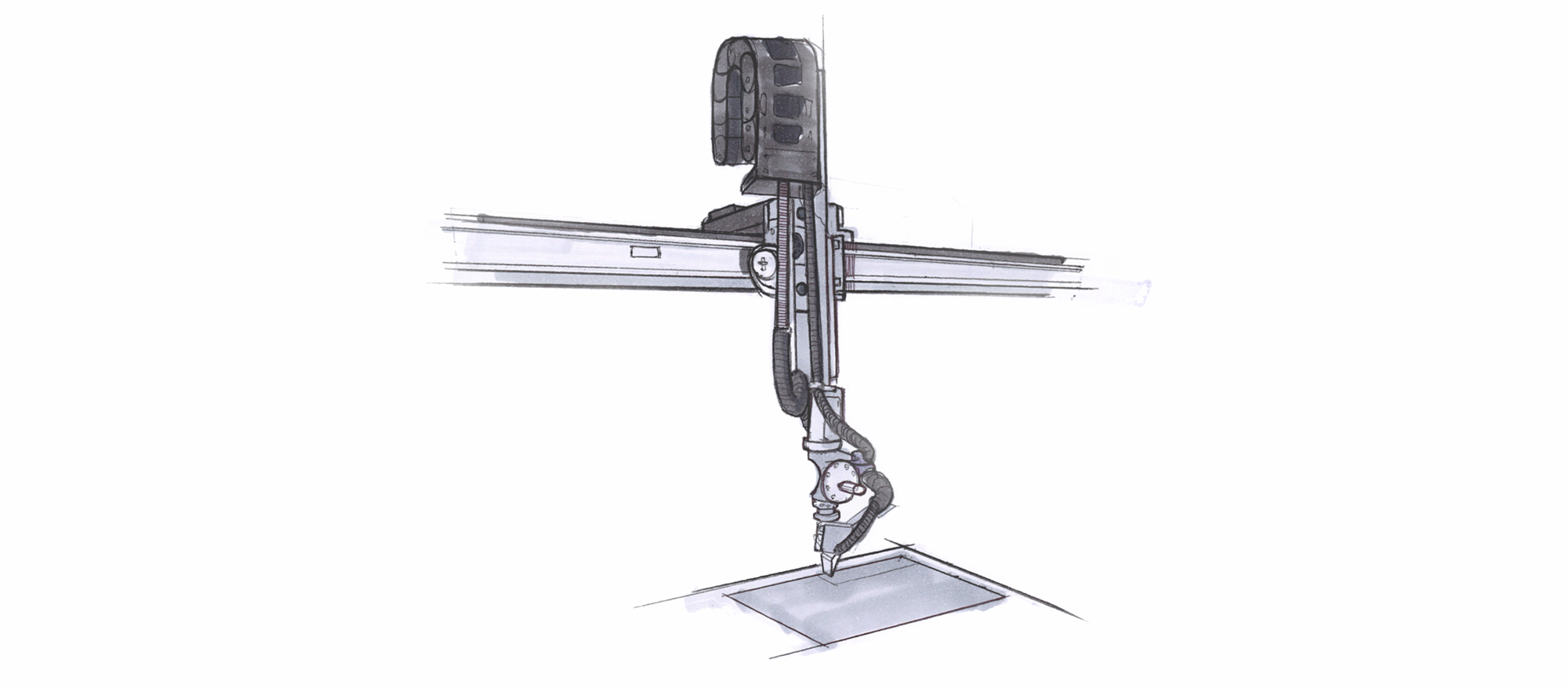

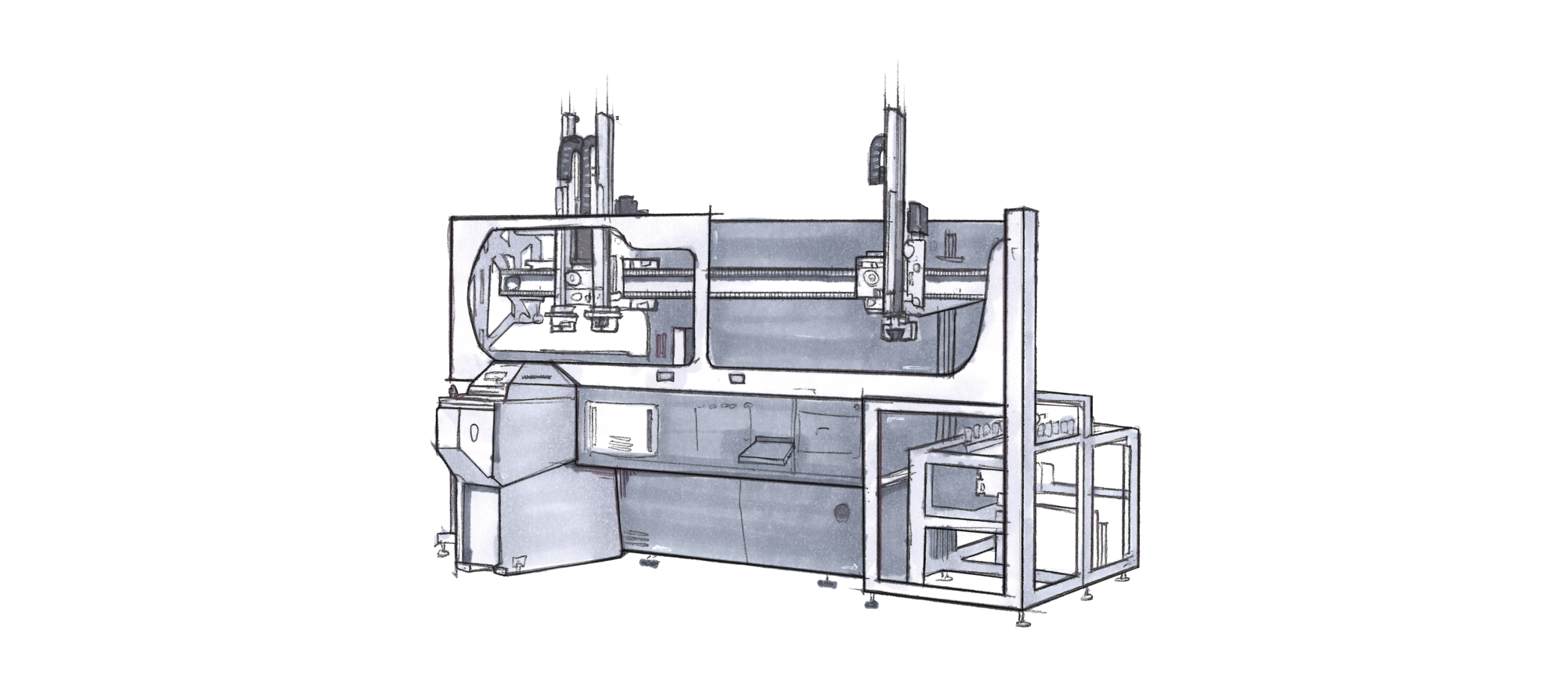

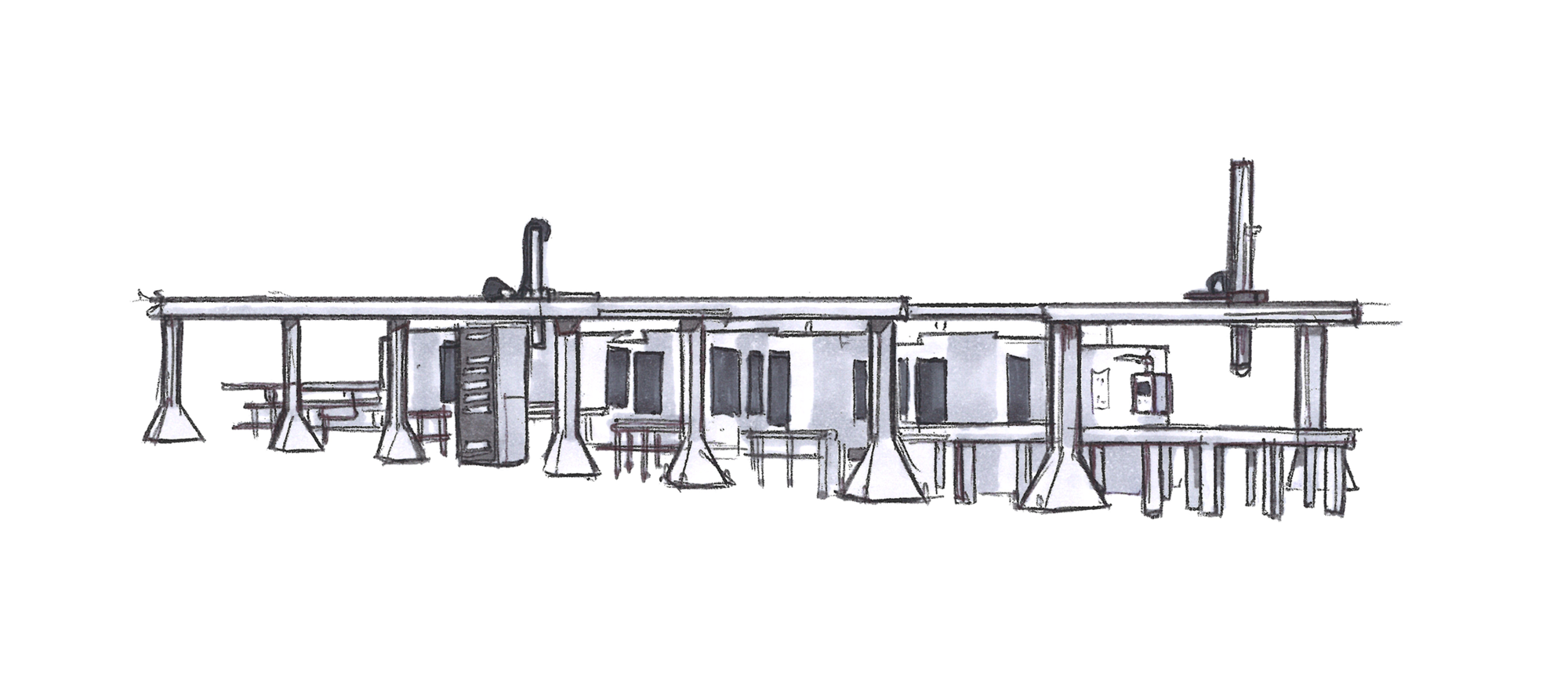

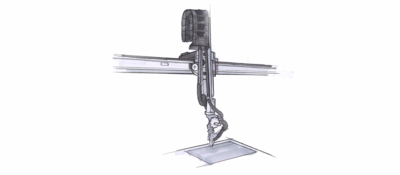

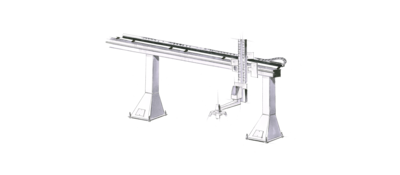

Loading machine toolsEfficient handling of workpieces and tools |

Loading machine toolsEfficient handling of workpieces and tools |

Details |

Our gantry solutions and individual components are perfectly suited to automated machine tool loading, and can be fully integrated into a wide range of machine tools. In this way, workpieces and tools of various shapes and sizes can be inserted into and removed from the machines with precision and reliability. With our broad portfolio of linear drive technology components, the travel movements of the process axes can likewise be realized in the machine tool. Through the use of high-quality components from our own manufacturing facilities, we can guarantee a long service life and low maintenance costs at the same time. High travel speeds and extraordinary precision are just two of the outstanding features of our linear robots. Our gantry solutions and components will help you increase productivity and process quality in your workpiece machining operations.

Interested?

|

,8084, | ,, | modal-solution-8804 |

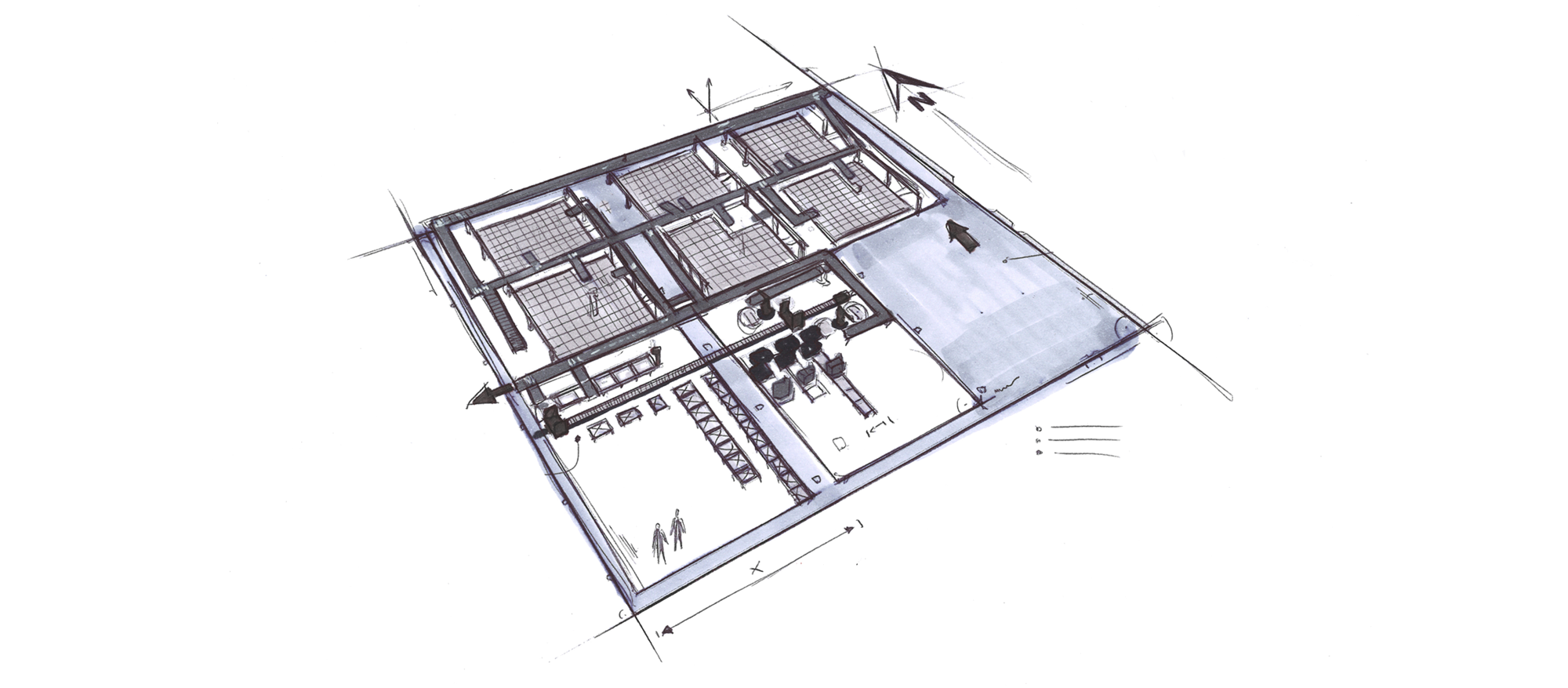

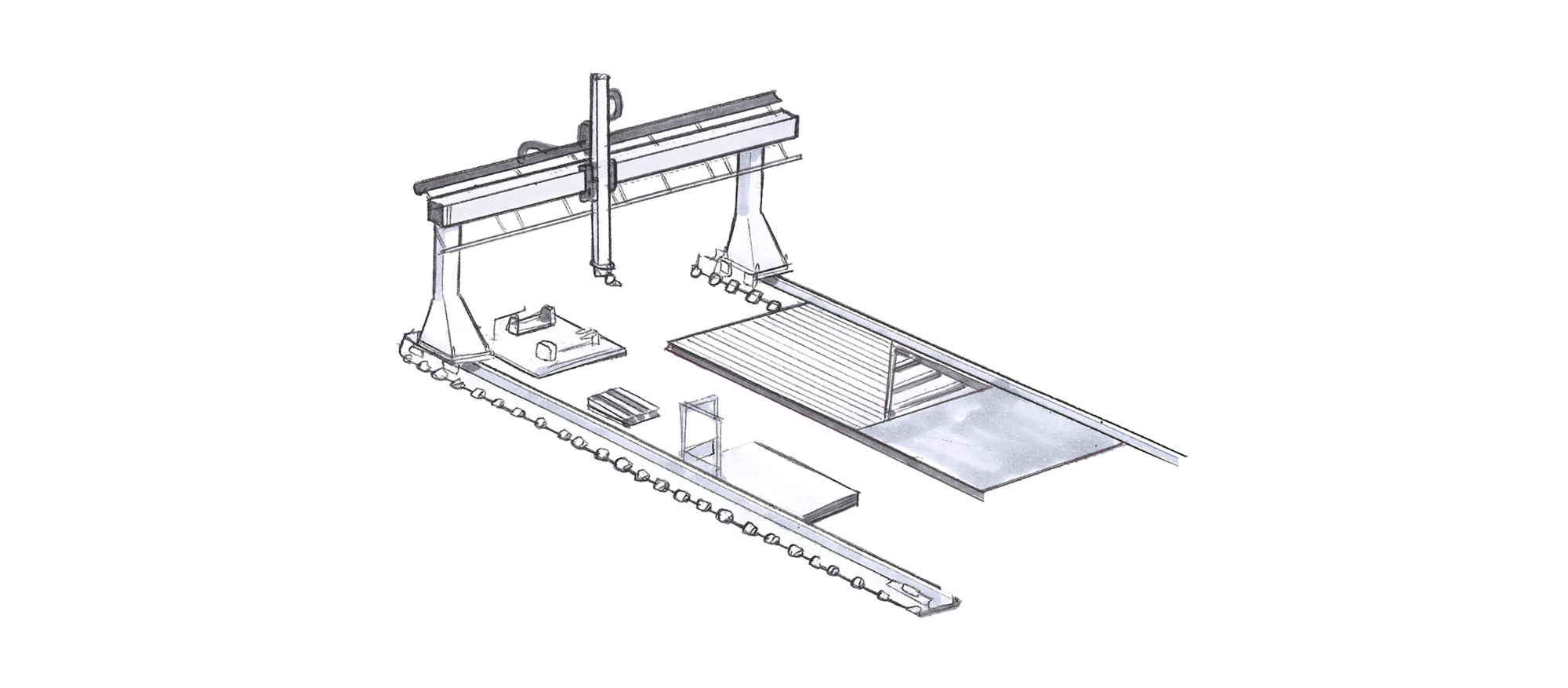

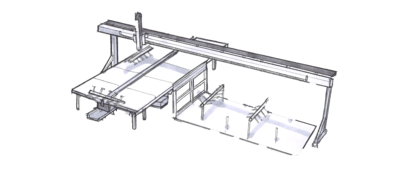

Multi-functional gantry for prefabricated elementsOptimal fixing and finishing of large hybrid components |

Multi-functional gantry for prefabricated elementsOptimal fixing and finishing of large hybrid components |

Details |

Our gantry robots enable the optimal integration of process steps such as storing, picking up, putting down, fixing, and finishing large hybrid components. Even heavy parts can be processed easily. The system is designed for grippers up to 400 kg.

Interested?

|

,8089, | ,7770, | modal-solution-7990 |

Powertrain automationThe powertrain is the beating heart of every automobile |

Powertrain automationThe powertrain is the beating heart of every automobile |

Details |

The drive train is the beating heart of every automobile. The handling, assembly, and processing of the various workpieces needs to be equally precise and reliable. For all these tasks, we offer sophisticated solutions that will make your production process flow much more smoothly.

Interested?

|

,8088, | ,7768, | modal-solution-7960 |

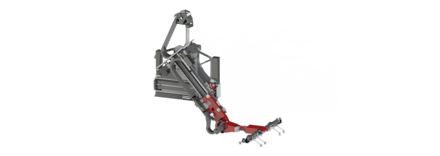

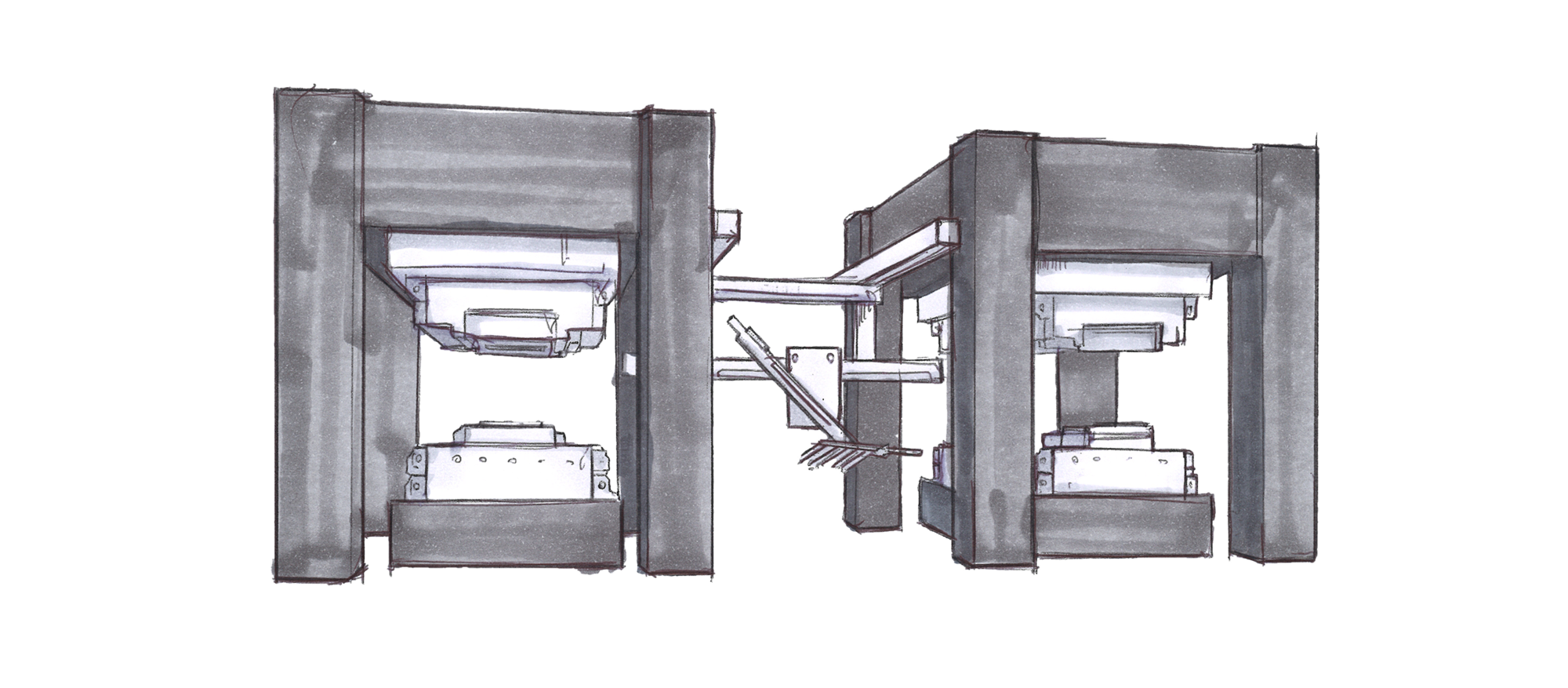

Press line automationUp to 21 parts handled per minute |

Press line automationUp to 21 parts handled per minute |

Details |

For a smooth flow, even between presses: our sophisticated parts transfer system can handle up to 21 parts per minute with speed and reliability guaranteed. Our transfer robots are characterized in particular by rigid mechanics and highly dynamic, low-vibration movements.

Interested?

|

,8088, | ,7766, | modal-solution-7987 |

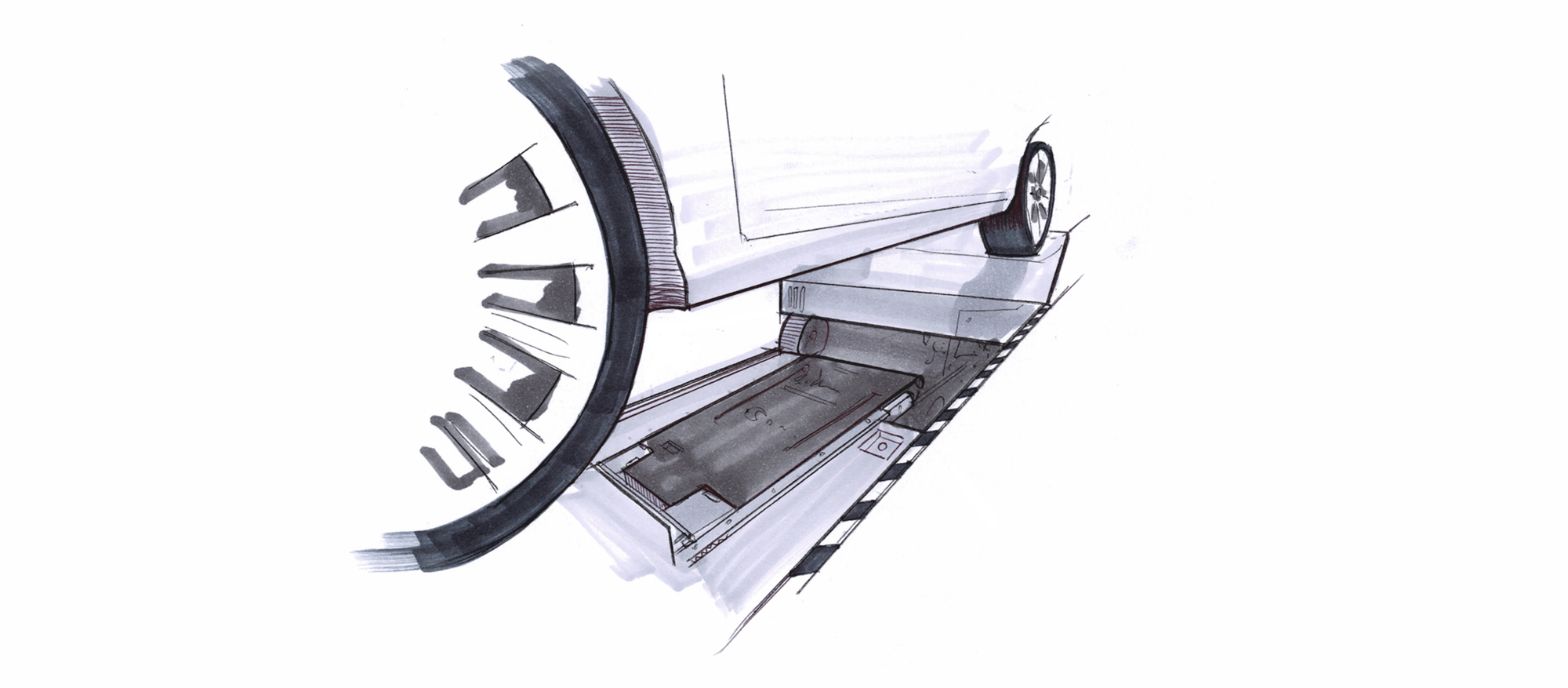

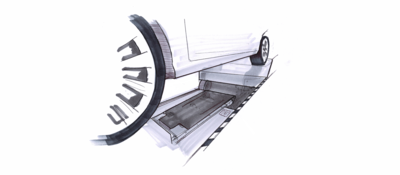

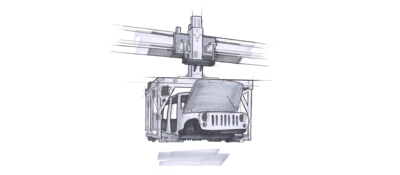

Replacement of rechargeable batteriesDrive through solution with fully automated replacement |

Replacement of rechargeable batteriesDrive through solution with fully automated replacement |

Details |

Güdel is contributing to the future of mobility with sophisticated solutions. Our systems offer a drive-through solution with the smooth, fully automated replacement of car batteries.

Interested? |

,8095, 8088, | ,7789, | modal-solution-7993 |

Solutions for bonding componentsEfficient handling of large components |

Solutions for bonding componentsEfficient handling of large components |

Details |

Our gantry technology is the perfect solution when large components have to be securely bonded. Using our solutions for the automated application of a dual-component adhesive to various geometries and components can efficiently streamline your work process, thereby making for a much smoother production process. Interested? |

,8086, | ,7785, | modal-solution-7999 |

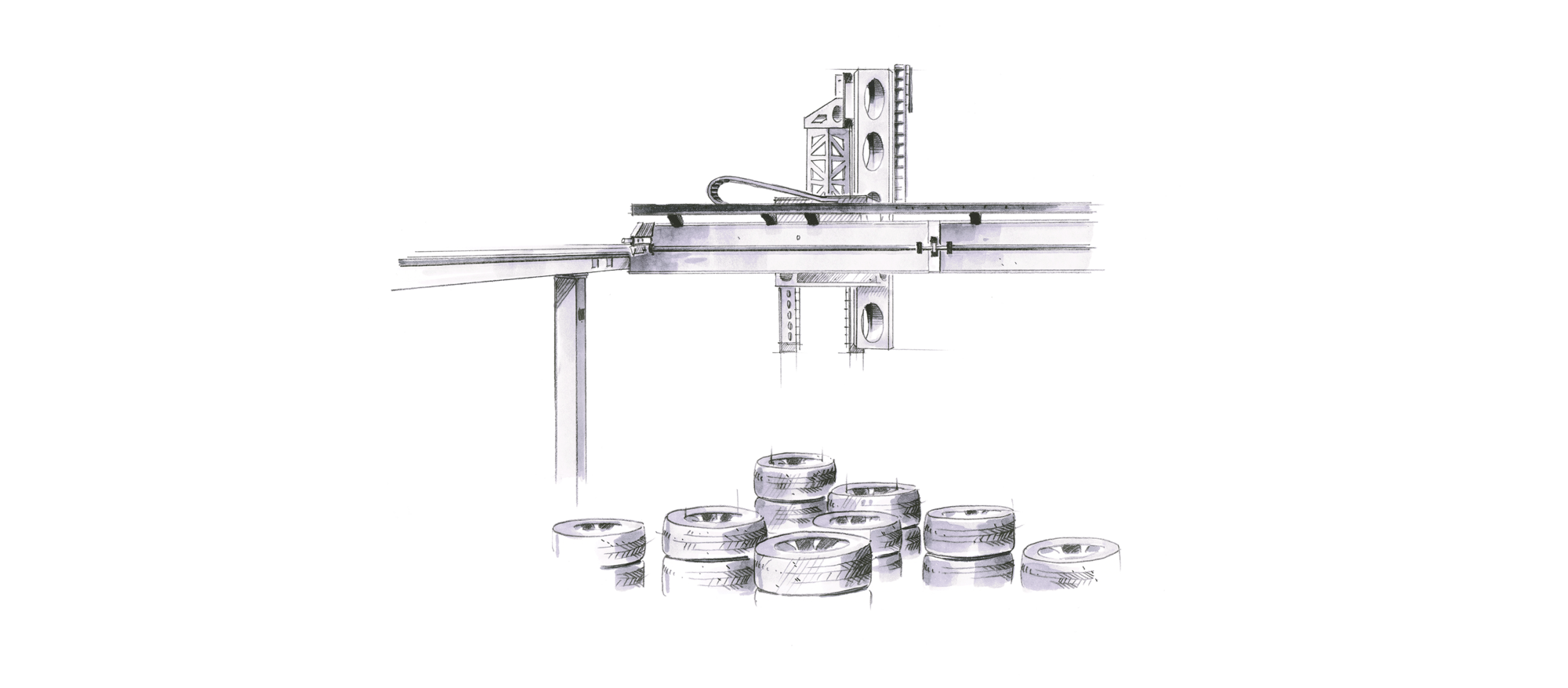

Sorting, storing and palletizing of finished tiresEfficient handling of finished tires |

Sorting, storing and palletizing of finished tiresEfficient handling of finished tires |

Details |

Sorting, storing, and palletizing your tires: Güdel's solutions allow you to automate all post-vulcanization processes right up to the shipment of the finished tires. Our modular concept means that all Güdel products are scalable and can be easily adapted to individual requirements and budgets. So you have the flexibility to decide just how much automation you want to introduce into the process chain. Whether you need individual components or turnkey solutions including material flow control, warehouse management, conveyor technology, and after sales-services: we offer all that you need to optimize your material flow.

Interested?

|

,8300, | ,8459, | modal-solution-8452 |

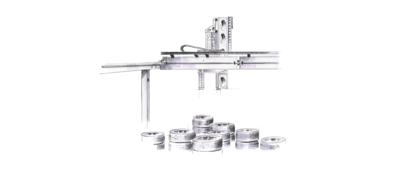

Storing, commissioning and palletizing of wheelsJust-in-time and just-in-sequence delivery |

Storing, commissioning and palletizing of wheelsJust-in-time and just-in-sequence delivery |

Details |

Güdel offers automation solutions especially for wheel assembly systems, that include sorting, storing and palletizing wheels from assembly up to shipment. Whether your particular situation requires a complete turnkey system including material flow control, conveyor technology and warehouse management or simply individual components, our modular concept means that we can always offer you the perfect solution for your requirements and your budget.

Interested?

|

,8300, | ,7787, | modal-solution-8457 |

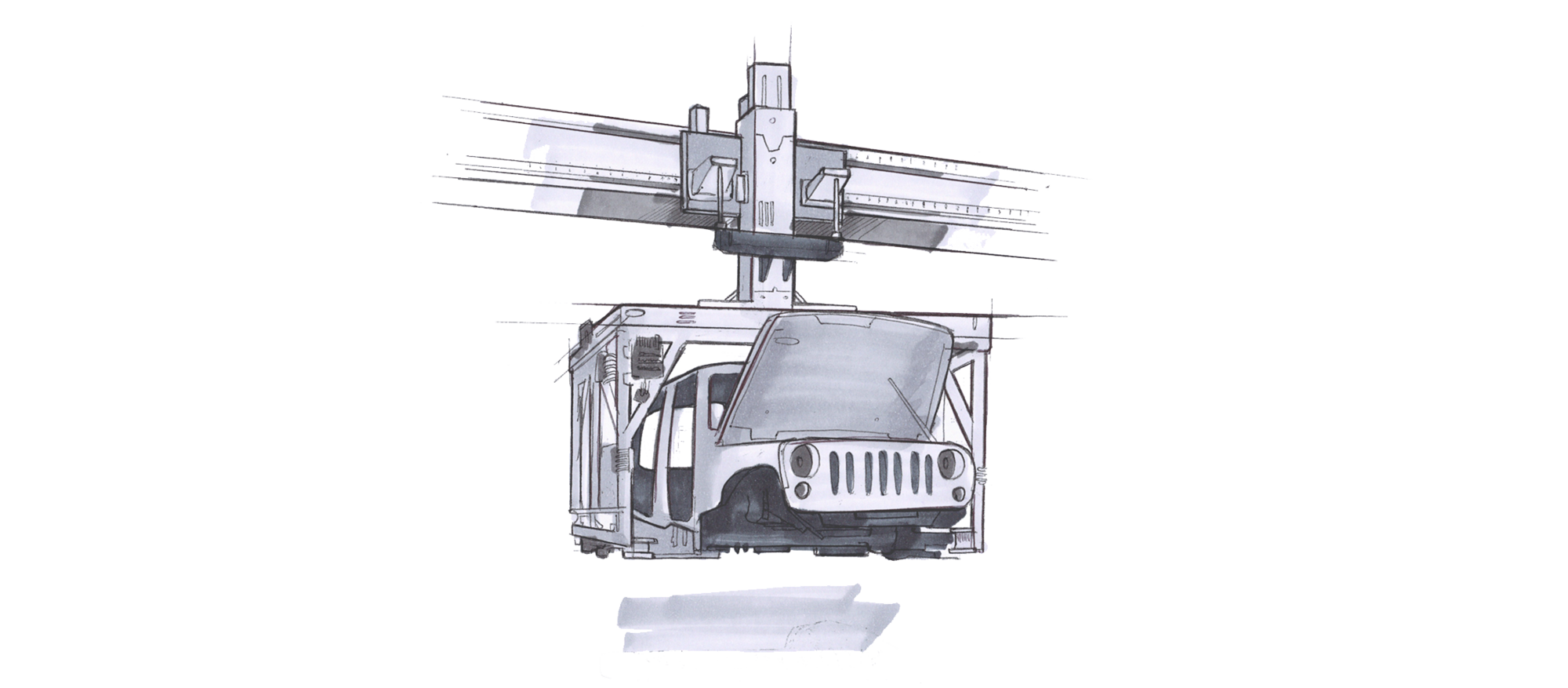

Transport and processing automationThe efficient linking of the individual processing stations |

Transport and processing automationThe efficient linking of the individual processing stations |

Details |

The greatest potential for optimization in body-in-white production lies in the efficient linking of the individual processing stations. The smoother the workpiece flow from station A to station B, the more efficient the whole process. We have a whole series of solutions for various requirements in this precise area.

Interested? |

,8088, | ,7769, | modal-solution-7988 |