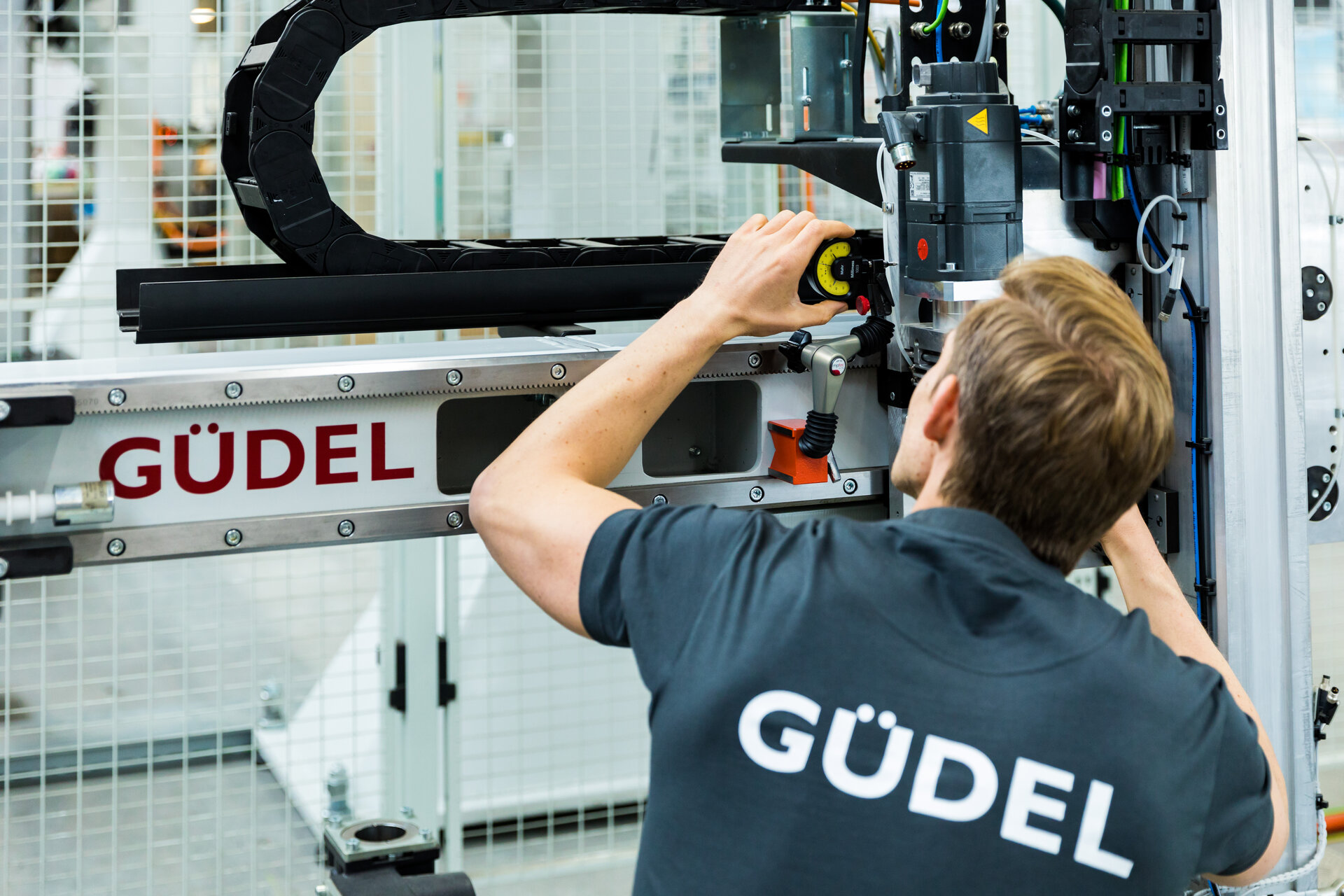

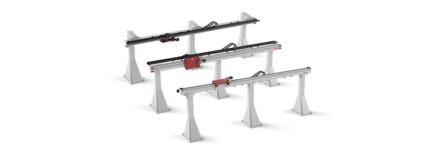

Condition monitoring for linear tracks and gantries

To increase your overall equipment effectiveness

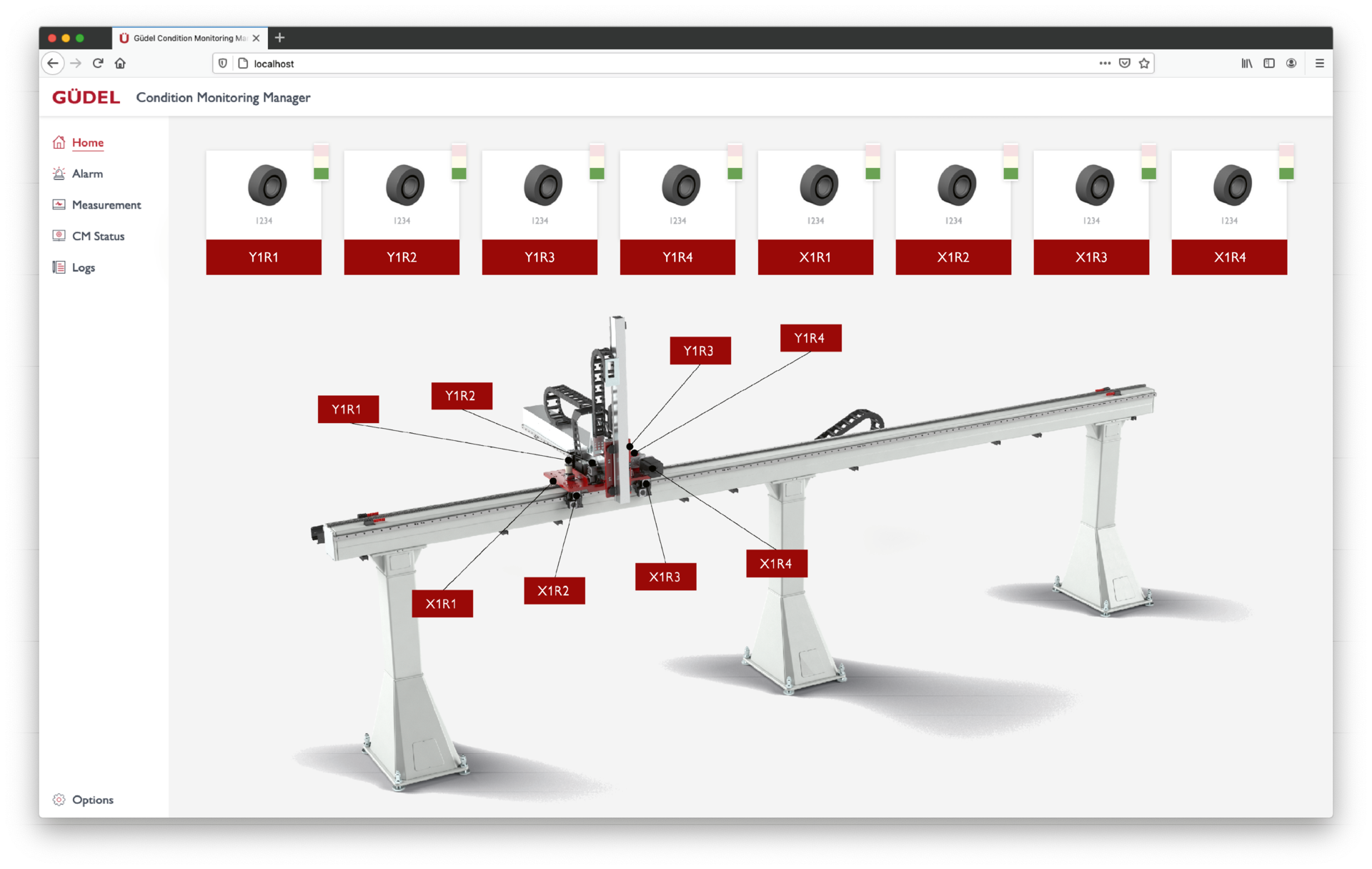

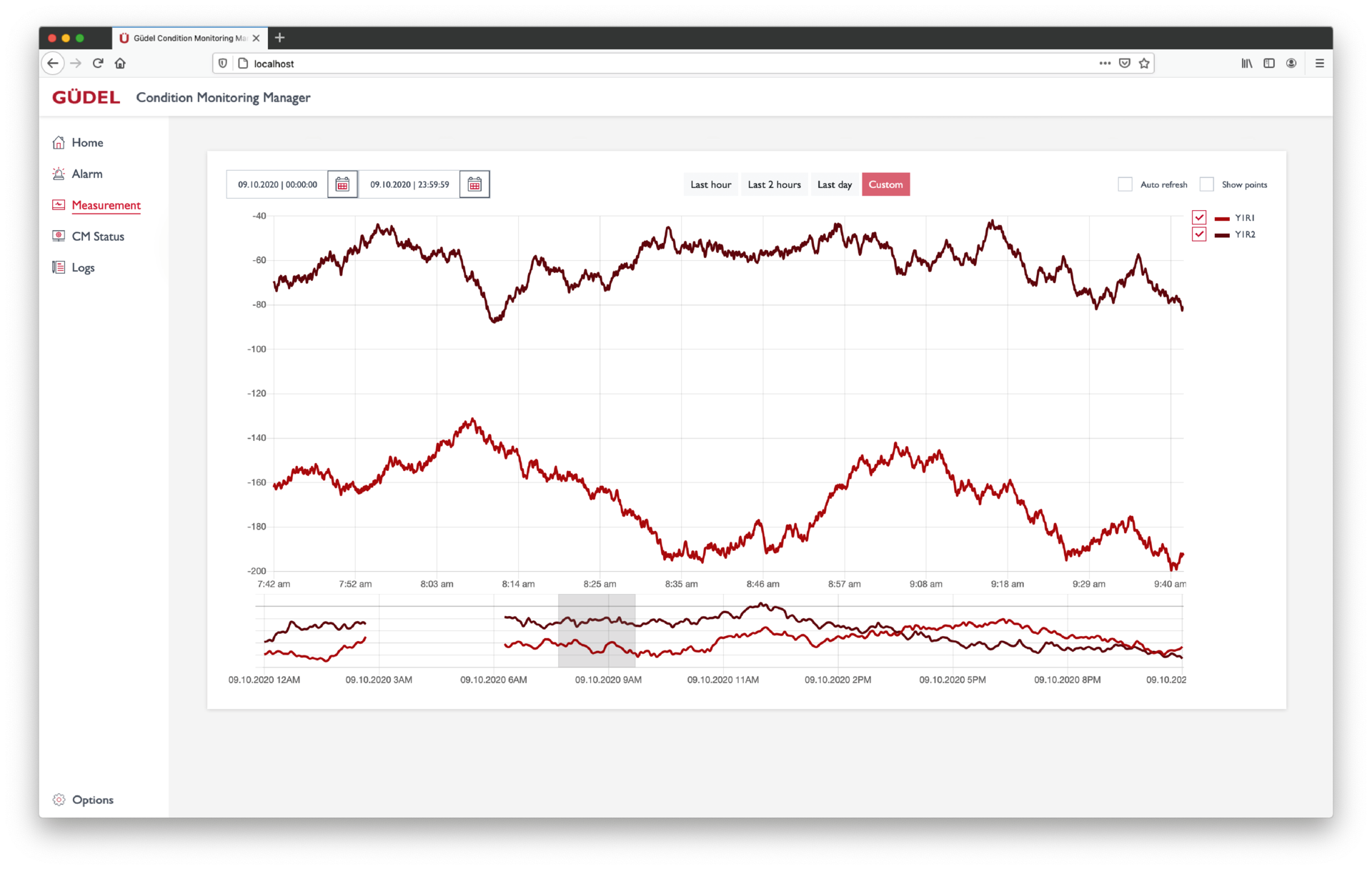

The condition monitoring package promises to increase the machine availability significantly and to anticipate unexpected production breakdowns proactively. The measured values of the components are accessible through the comprehensive dashboard. The calculated condition will be displayed by a light system.

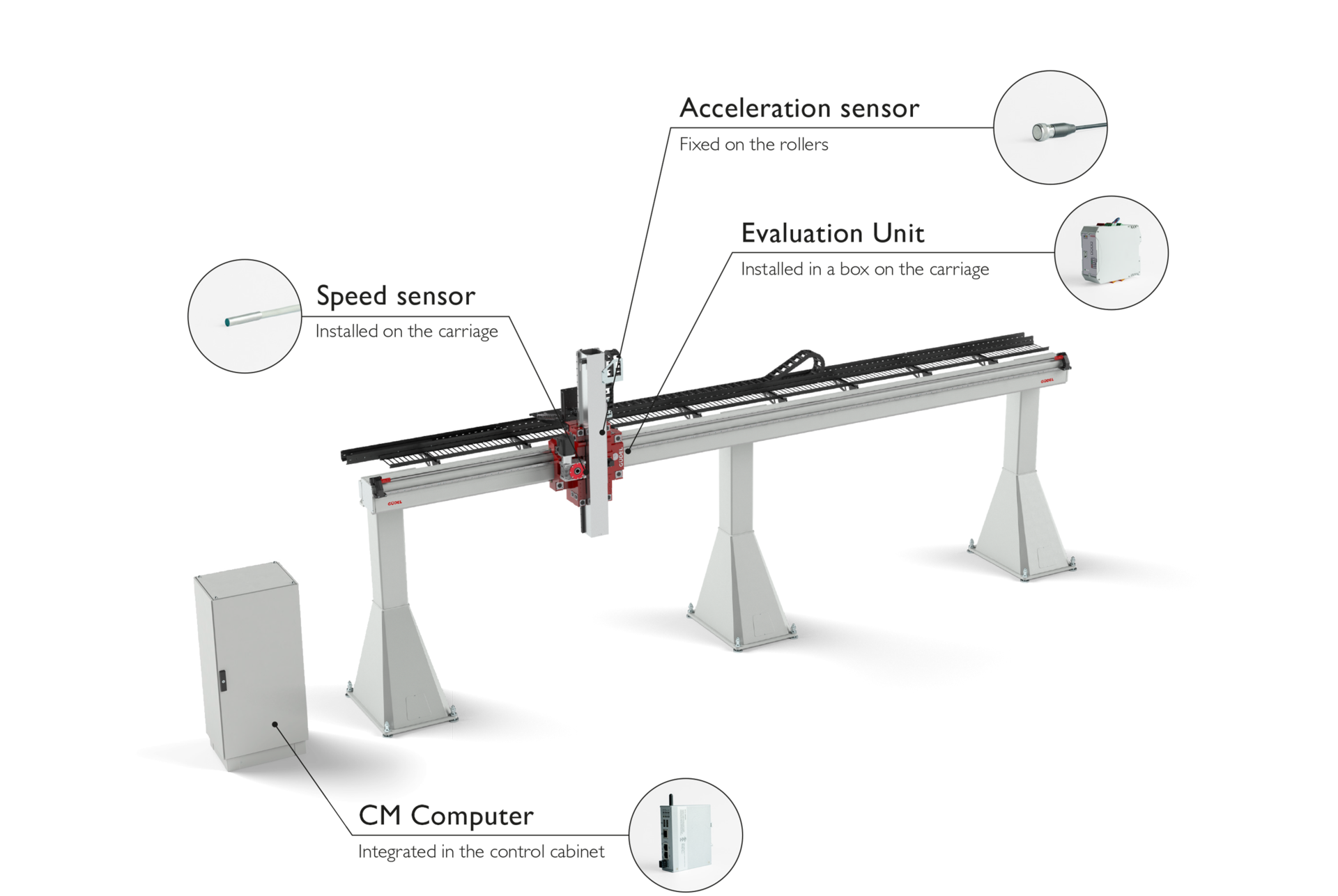

Sensors and evaluation units are matched carefully to create a stable and independent working function package.