Racks & pinions

Perfectly matched to every application

Find the right rack – High-End, Performance or Basic

Complemented by the right pinion, our product lines offer optimally coordinated solutions for a wide range of applications. The racks are designed for common application scenarios and can be integrated directly into your systems thanks to their sophisticated technology. For specific requirements beyond our standard range, our semi-finished product system offers a cost-effective and fast solution.

Technical data, CAD models, and data sheets are available for download.

Contact us for customized solutions tailored precisely to your application.

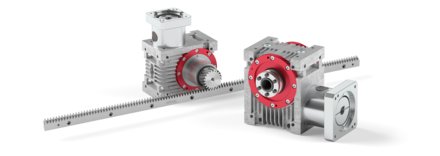

High-End

Maximum performance

and lifetime

For the highest demands in linear drive systems of all types of modern machine tools, process equipment and automation systems with the highest quality requirements. Ultra-high load capacity and maximum feed force in given installation spaces enable downsizing through outstanding power density, thanks

to hardened tooth roots.

Performance comparison High-End

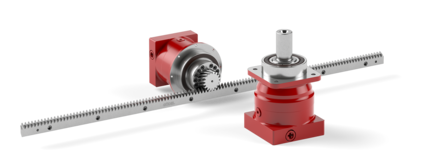

Performance

Maximum precision

and smooth operation

Precision-ground and hardened tooth flanks ensure highly accurate positioning. Ideal for applications requiring the highest precision. These racks are particularly suited for applications with medium dynamics and precision demands, such as laser cutting machines, plasma and waterjet cutting systems as well as tube bending machines.

Performance comparison Performance

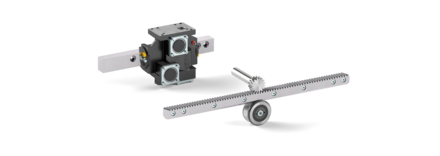

Basic

Reliable androbust

design

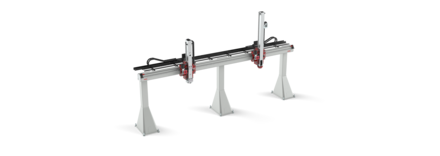

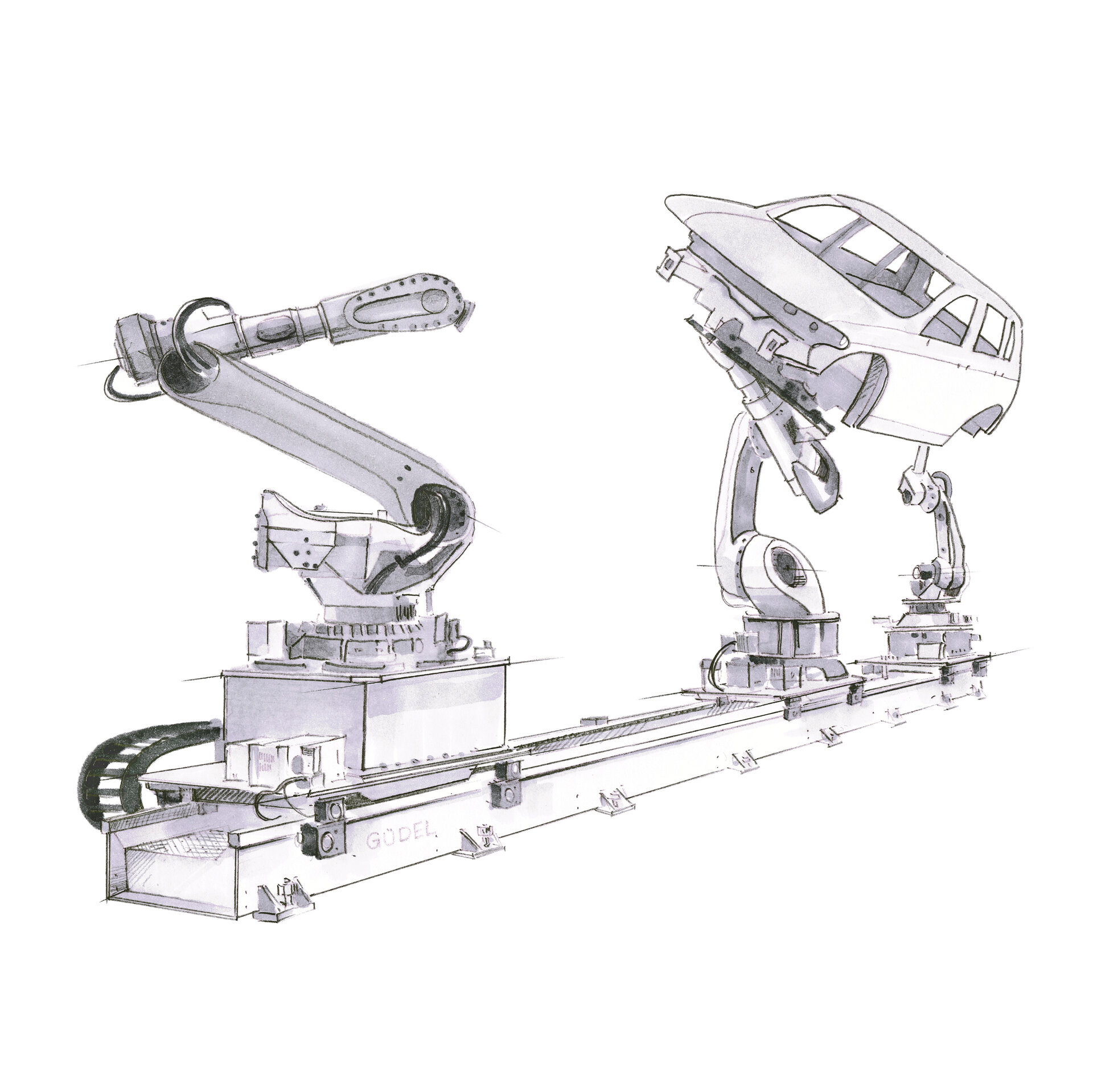

Milled and hardened racks for solid power transmission. Perfect for applications with lower precision requirements. Increased feed force requirements combined with standard precision ― for example in automation gantries, pick-and-place applications and

robot travel axes.

Performance comparison Basic

Things to know about racks & pinions ― versatile, precise, customizable

Our portfolio of racks and pinions includes various designs, performance parameters and quality classes ― designed for a wide range of industrial applications. In addition to our standard range, we also offer the option of implementing customer-specific special designs. We tailor these precisely to your industry and your requirements. With our experience and vertical integration, we ensure that you receive the right technical product for every application.

Performance comparison of product lines High-End, Performance oder Basic

You can achieve maximum precision and performance with our new High-End line, while the Performance product range delivers proven Güdel quality. Basic is the right choice for Pick & Place, applications in logistics / material handling.

The requirements for the feed force to be transmitted result from the desired dynamics or acceleration and the mass to be moved.

Given the available installation space for module 2, high-end racks transmit the greatest feed forces by far.

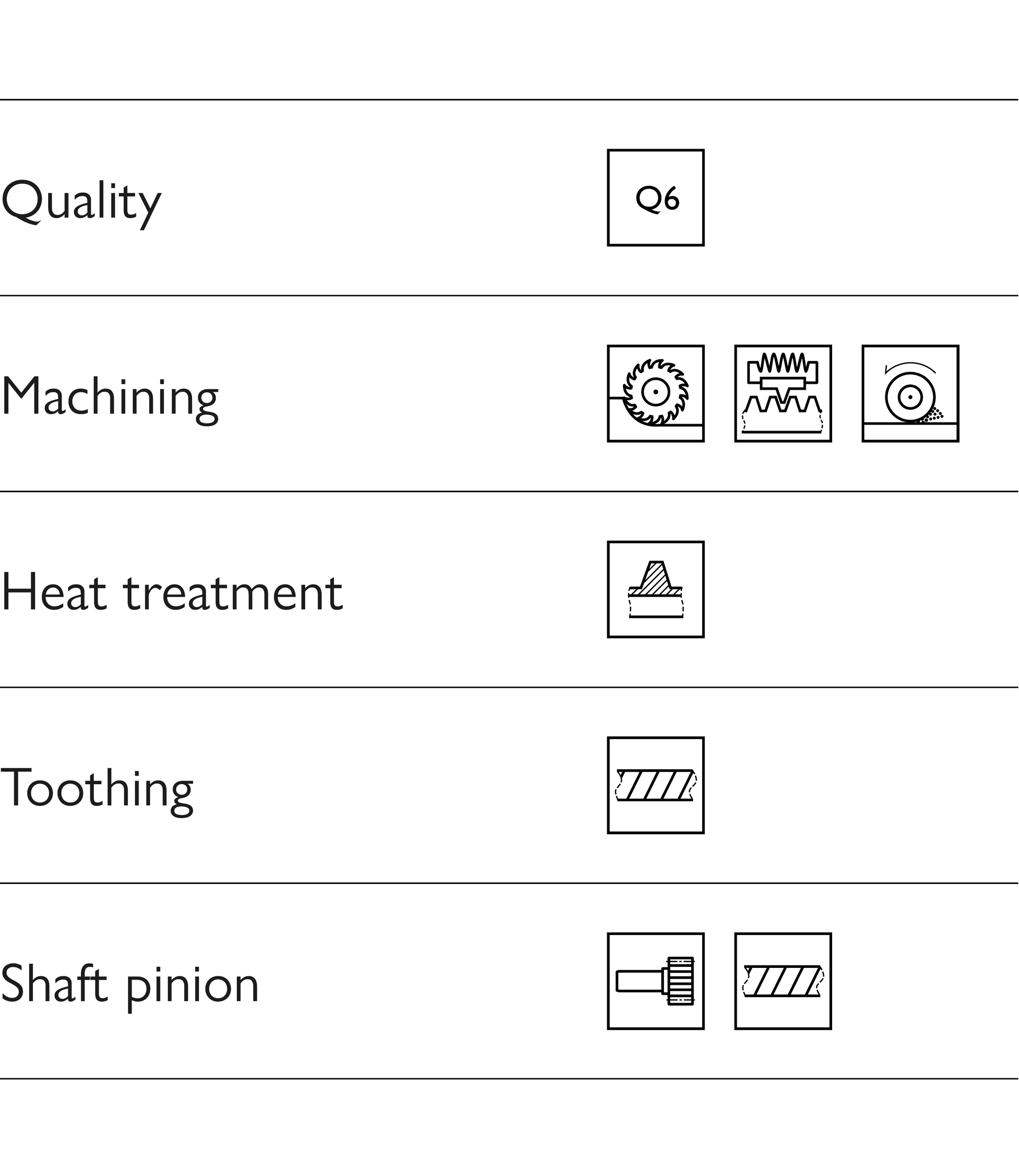

Comparison of quality characteristics at 1000 mm / module 2.0

Our standard program covers all common tolerance classes. Güdel offers different quality classes depending on the accuracy requirements.

Racks in quality 6 are ideally suited for the assembly of long axes and rack-and-pinion drives, which are characterized by low clearance. Use quality 8 or 9 for applications with lower accuracy requirements, such as pick-and-place tasks.

Force vs. number of load cycles, Module 2.0 | Pinion teeth count z = 20

Our high-end racks also offer a particularly high load capacity and long service life in the same installation space.

Thanks to the precise production and high performance, the feed forces remain constant even with many load changes - without any loss of fatigue strength.

Downsizing without compromise: Lighter, but just as powerful

Less weight, same performance – that’s exactly what the new high-end racks deliver. For example, a module 2 high-end rack can replace a module 3 performance rack. This reduces the weight from 5.6 to just 4 kilograms. Over a distance of 30 meters, this adds up to a weight saving of up to 48 kilograms.

The advantages are obvious: lower drive loads, easier handling and potentially lower system costs. A real gain in efficiency – without compromising on performance.

Calculation of racks and pinions

First of all, determine the maximum Application force F2b_Max in the left part (gray) of the flow diagram. Distinguish whether the axis is horizontal or vertical.

Then evaluate the load capacity according to the right-hand part (red) of the flow diagram. Select a suitable rack and its bearable feed force from the finder or the technical data sheets depending on the load case.

The comparison may have to be repeated until a suitable rack was found.

Related Products

Contact

We are pleased to answer your request

Get updates about the latest developments of our products, current news, information about events and the latest content on our website.